Page 6 of 7

Posted: Wed May 23, 2007 8:38 am

by Gary57

I am currently speaking with a company on the States to create a custom "Chip"with all my modifications and fuel "Ron" for me to solder into my ECU based off a "mines" tune.

You can take my ECU with daughter board, then no need to solder and unsolder

.

I'm aiming at 180 Wkw at 0.8 Psi / 055 bar

Thats some serious power for 0.55Bar

.

Posted: Wed May 23, 2007 9:04 am

by Phinx

Hmm nope I haven't contacted " Horsham".

Will get there E-mail address now.

You can take my ECU with daughter board, then no need to solder and unsolder Laughing .

I made you an offer it still stands if you interested.

Thats some serious power for 0.55Bar Confused .

I'm sure it can be done a wise man once told me is all about flow.

The less of a restriction you can make the less "boost needed to make power because the flow is un-restricted.

Posted: Wed May 23, 2007 9:17 am

by Gary57

The less of a restriction you can make the less "boost needed to make power because the flow is un-restricted.

That is true but power is factor of cylinder pressure, the more pressure the more power (very vaguely speaking), do you think the stock setup is that restrictive?? I know the plumen is very restrictive.

But with cams I sure you will make it, good luck.

I made you an offer it still stands if you interested.

That offer needs to go up slightly

.

Posted: Wed May 23, 2007 9:55 am

by Phinx

That offer needs to go up slightly.

Ok I will offer you R50 more?

And your right but it an easy and not the best way of tunning.

Its about how effectively you can fill the cylinders , At the same time decreasing losses (heat losses because of increased pressure) and more effectively using that energy

Ok its more complicated then that but that works.

Posted: Wed May 23, 2007 10:11 am

by Gary57

Ok I will offer you R50 more?

Haha a bit more than that

.

Well I made 170-180RwKw odd at 0.8 and I know my boost pipes are restrictive, so once the new cooler and pipes are in I will definately see a difference. My goal is 200RwKw, but I think Ill stop after the FMIC maybe a few small mods here and there but nothing major.

Posted: Thu Sep 13, 2007 11:39 am

by Phinx

Good Morning Guys....

Long time no update... .

As you know the car blew it head gasket again .

So now I'm going to build in some reliability..

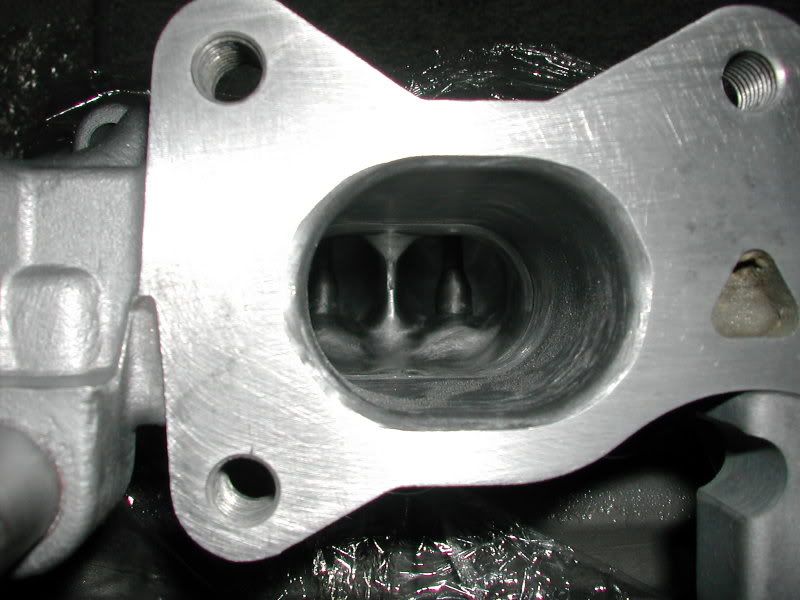

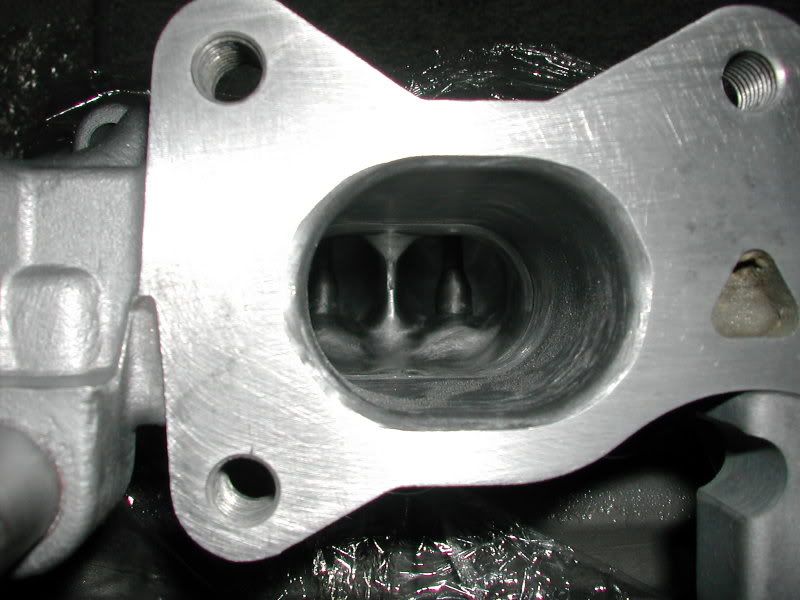

You will not believe how unmatched the intake is to the head on the Ca18det.

Now its dremel time ....

I also got the Spares needed to do the rebuild...

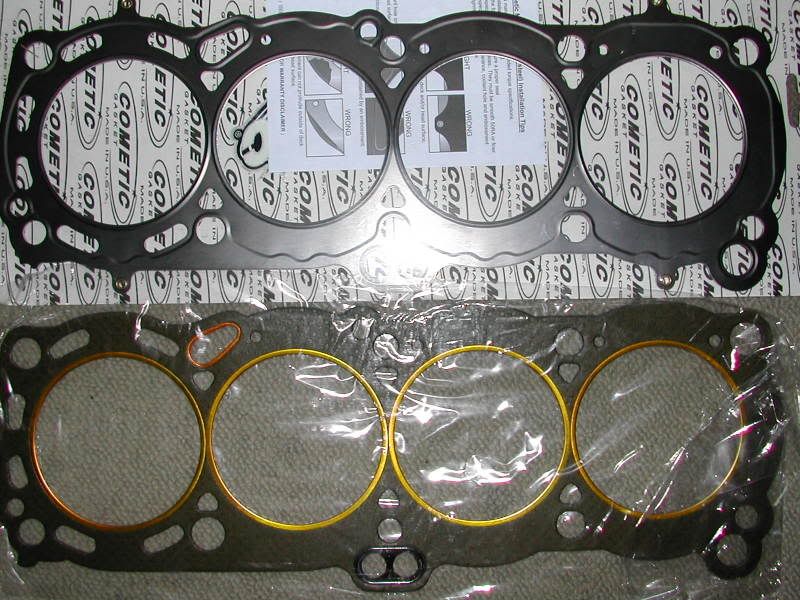

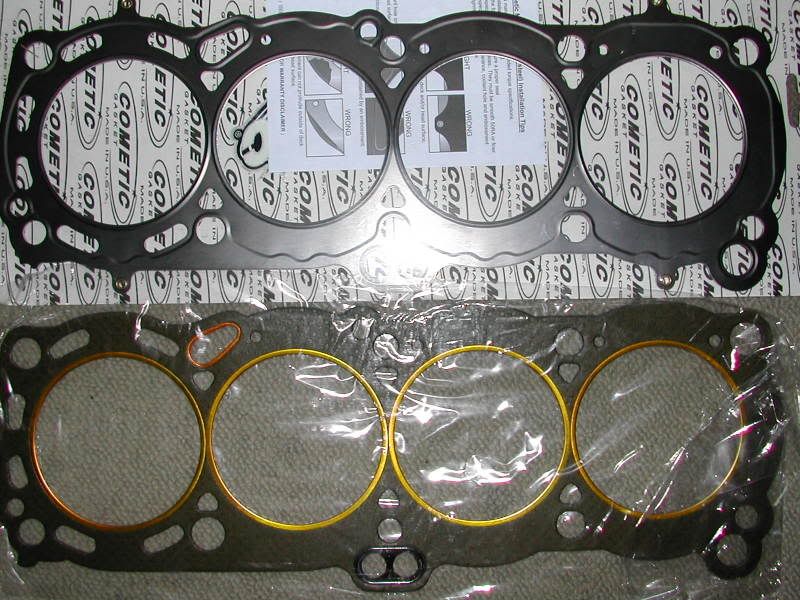

Head Gasket compare... Stock Vs Cometic

I also got the head back, Fully redone new stem seals and seats...

Full Port and polish, CC'ed and Combustion chambers done.

Combustion Chambers

Exhaust Port...

Intake port

Ported Intake manifold on new head

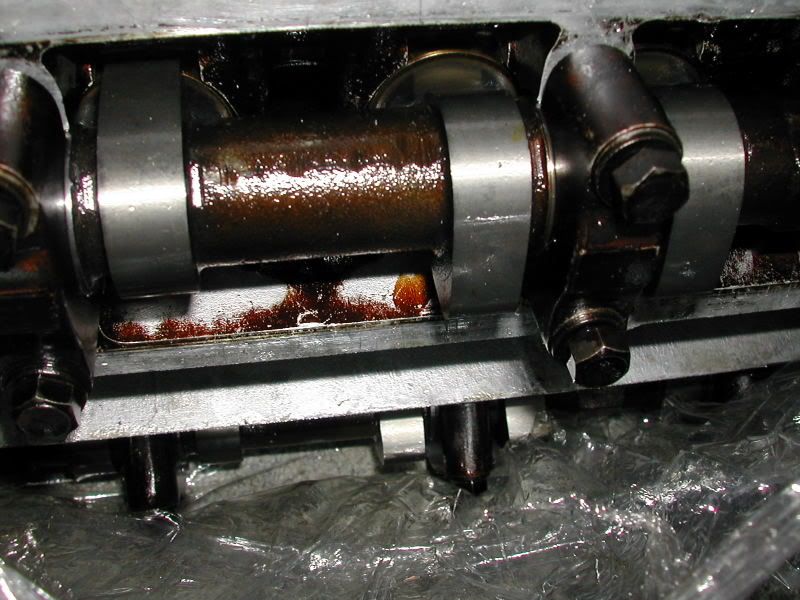

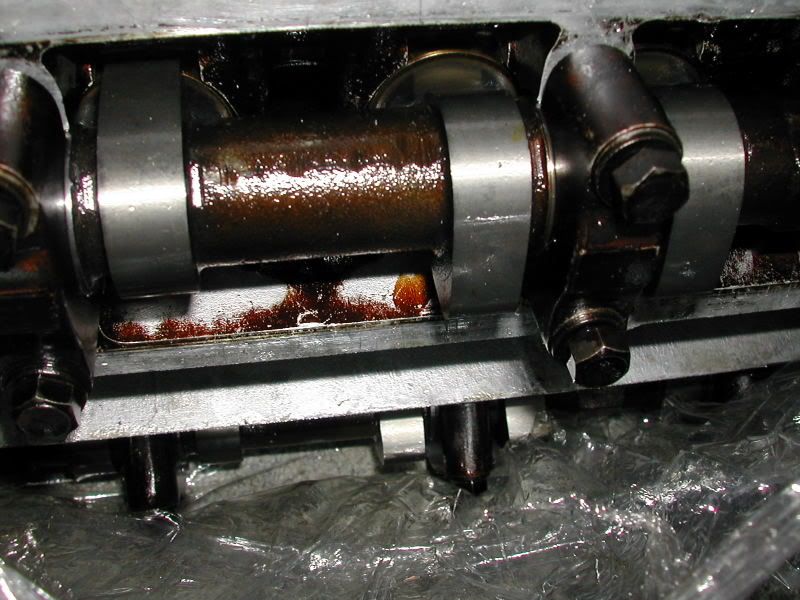

And finally a nice set of cut cams

Posted: Thu Sep 13, 2007 11:44 am

by Gary57

VERY VERY nice stuff there.

Posted: Thu Sep 13, 2007 12:13 pm

by veecee

eish!!!

its gonna be cool maneer!!! even more powa!!!

Posted: Thu Sep 13, 2007 1:01 pm

by Draco

Fu**er!!!!!!

Posted: Thu Sep 13, 2007 1:18 pm

by Vlade

Nice work there Phinx

Posted: Thu Sep 13, 2007 1:20 pm

by Draco

Ya nice....fu**er

Posted: Thu Sep 13, 2007 1:53 pm

by Phinx

I just need to finish the port matching...

I cant believe Nissan even shipped the motor with ports so mismatched.

The Lower intake will get a full polish and the stock intake will be fitted untill something arrives

Posted: Thu Sep 13, 2007 1:57 pm

by veecee

hmmm...

where's my dremel tool i wonder!!!???

maybe you got a friday motor???

Posted: Fri Sep 14, 2007 6:04 pm

by jon

Looking good Phinx, looking forward to your results

Posted: Mon Sep 17, 2007 6:29 pm

by The Calibrator

I am about to become unpopular but I feel the need to correct a terrible mistake I see being perpetuated.

Where the port is "matched" to the gasket is an abortion. You cannot "round' the port out to the gasket line as it creates terrible turbulence and destroys the flow.

The port must taper in gradually and evenly from the gasket over as long a distance as possible for the best results.

Any head porter who does ports like that should have his nuts removed withy a pair of rusty pliers.

You need to "think" like air it has inertia and mass it doesnt like sudden changes in direction and wont flow anywhere near your gasket line howver the sudden divergence and convergence will cause massive turbulence and screw up all your hard work.

YMMV